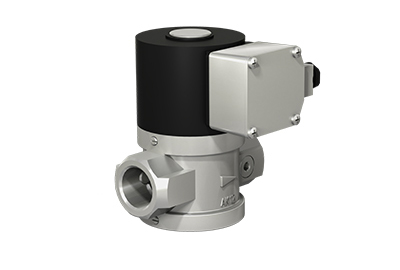

SOLENOID SAFETY GAS VALVES

Solenoid safety gas valve (the valve) is a device designed for usage in systems where remote control of the flow of non-aggressive gaseous medium and liquids is required.

OPERATING PRESSURE:

Operating pressure range of the valve (ВН and BF type):

- 0 to 6 bar (mPa);

- Operating pressure is a maximum overpressure at which adjusted operating mode is maintained.

NOMINAL DIAMETER:

Nominal diameter range of TERMOBREST valves: 15 to 300 mm. Such wide range of nominal diameter types allows covering all demands of the market of gas equipment of low, medium and high pressure.

INITIAL STATE:

- normally closed (closed in de-energized state);

- normally opened (open in de-energized state).

HOUSING MATERIAL:

- steel: DN15÷300;

- cast iron: DN-150, DN-200;

- aluminum: DN15÷200.

Valves in aluminum and cast iron housings are applied at thermal power facilities (boiler houses, furnace rooms etc.), technical gas lines of different plants and factories (chemical, petrochemical, extractive, food, building materials etc), and also by manufacturers of gas equipment (modular boiler houses, boilers, burners, furnaces, flare facility etc). Low weight, cost and small dimensions make valves in aluminum housings practical in application.

Valves in steel housing are applied primarily at large power plants (heat and thermal power plants, condensation power plants etc). Steel housings are highly resistant to static and dynamic loads due to requirements of equipment application at large power plants.

CLIMATIC VERSIONS:

- -30…+60 °С – operation in irregularly heated space;

- -45…+60 °С – operation under cover;

- -60…+60 °С – operation under cover;

- -60…+60 °С – outdoor operation (only for explosion proof version).

OPERATING ENVIRONMENT TEMPERATURE:

By default, all gas valves manufactured by TERMOBREST are supplied in a version designed for working environment with temperature range from -60 to +70 ° C. By special order the valves can be manufactured for working environment with temperature range from -45 до +120 °С.

BY ITS FUNCTIONALITY AUTOMATIC SOLENOID VALVE CAN BE OF TWO TYPES SHUT-OFF VALVE AND SHUT-OFF CONTROL VALVE:

Shut-off valve

Shut-off control valve

- Shut-off valve ensures fast opening/closing (operation time 1 second max) and is applied in systems, where it is necessary to stop medium flow in emergency situation or by technological requirements. Also such valve is applied to control medium supply in gas facilities.

- Shut-off control valve ensures fast opening/closing as well as adjustment of the medium pass in open state of the valve. Shut-off control valve is applied to control medium flow, ensuring necessary operating modes of gas facilities and devices. Control of medium adjustment can be both in manual and automatic modes.

ADDITIONAL FUNCTIONS AND DEVICES:

Valves of BH and BF type can be equipped with valve’s trim position indicator, which transmits information to the control board or automation about the current state of the trim (open or closed).

Besides that valves can be manufactured with manual start-up function of electric or mechanical type. Manual start-up function ensures guaranteed protection of the device from its inadvertent opening in emergency situation.

HOUSING TYPE:

Linear (standard)

Angle

Standard (linear version) valves are applied on the straight pipeline sections.

Angle valves are applied at the facilities with limited space (corner sections of the pipeline etc.) and allow reducing number of welding joints and connections during installation.

Flange (DN15÷300) connection

Coupling (DN15÷50) connection

Valves with flange connection are manufactured with flanges PN 6 (by default) or PN 16 (on request).

Valves with nominal diameter 15÷50 mm can be manufactured in monoblock unit version, i.e. two and more devices are unified in one housing. Such design ensures maximum functionality with minimal product dimensions.

VERSIONS:

General purpose industrial version

Explosion proof version

General purpose industrial versions of valves are applied at all gas facilities, where there are no special requirements for ensuring explosion safety of electrical equipment.

Explosion proof versions of valves are applied at the facilities and premises with special protective measures requirements upon designing, manufacturing and operating of electrical plants.

Explosion proof electrical equipment is a special type of electrical equipment that is designed to eliminate ignition of the explosive environment surrounding it during the operation of this electrical equipment.

-------------------------------------

If you need help to select necessary equipment, you should visit our web-site or contact our specialists by e-mail info@termobrest.ru or by phone:

+375 (162) 53-64-13 (technical consultation line);

+375 (162) 53-64-76 (sales and logistics department).

GAS PRESSURE REGULATORS-STABILIZERS

Pressure regulators-stabilizer is a device designed for reduction, regulation and maintenance of the pressure (flow) of hydro carbonated gases, gaseous phases of liquefied gases, compressed air as well as other non-aggressive gases constant at the outlet within prescribed limits regardless of inlet pressure. Pressure regulators-stabilizers can operate without external power source.

FIELD OF APPLICATION:

Gas distributing plants, heating plants, gas reciprocating engine power plants, gas burners and other equivalent equipment and installations, which require reduction and maintenance of the constant value of gas flow rate pressure.

MAXIMUM OPERATING PRESSURE:

- up to 6 bar

DIAMETER NOMINAL:

DN 15÷150

HOUSING MATERIAL:

- aluminum;

- steel.

VERSIONS:

1. Standard version (DN 15÷150) - designed for reduction, regulation and maintenance of the gas pressure within prescribed limits.

2. Regulator with in-built safety relief valve (DN 15÷150) – designed for reduction, regulation and maintenance of the gas pressure within prescribed limits and has function of gas discharge to the atmosphere (gas path) in case if controlled pressure is exceeded.

3. Combined regulator both with safety shut-off (DN25÷100) – designed for regulation and maintenance of the gas pressure within prescribed limits, and also stops gas supply, when prescribed gas outlet pressure is exceeded.

4. Combined regulator, both with safety shut-off valve and safety relief valve – designed for regulation and maintenance of the gas pressure within prescribed limits; has function of gas discharge to the atmosphere (gas path) when controlled pressure is exceeded, and also stops gas supply, when prescribed gas outlet pressure is exceeded;

Combined regulators-stabilizers can be manufactured in following versions:

- with safety shut-off valve and safety relief valve in separate housings.

- with safety shut-off valve and in-built safety relief valve.

- with safety shut-off valve and safety relief valve in one housing (monoblock unit version).

- combined household regulator, both with safety shut-off valve and safety relief valve. Such regulators are applied at the gas supply systems of residential and small-apartment houses as a part of household gas distributing plants.

5. Zero pressure regulator (DN 15÷150) - designed for proportional regulation of gas flow rate depending on rarefaction at the outlet or at the control point of pipeline, and maintenance of gas-air mixture in a constant ratio.

6. Gas-air pressure ratio regulator (DN 15÷150) - designed to obtain a gas-air mixture in the required ratio and automatically maintain this ratio.

CLIMATIC VERSIONS:

- -30…+60 °С

- -40…+60 °С

OPERATING MEDIUM TEMPERATURE:

- from -30 to +70 °С.

-------------------------------------

If you need help selecting necessary equipment, please visit our web-site www.termobrest.ru or contact our specialists by e-mail info@termobrest.ru or by phone:

+375 (162) 53-64-13 (technical consultation line);

+375 (162) 53-64-76 (sales and logistics department).