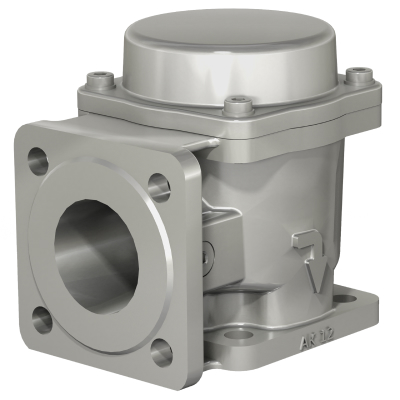

GAS FILTERS

Gas filter is a device designed for gas purification from mechanical particles (dust, rust (corrosion), sand fire scale and other solid particles) and it is installed in front of the shut-off and control fittings unit of gas-burning devices of hot water boilers, heat generators, infrared heaters and other gas-fired installations. It can be applied in measuring instruments (flow meters, meters, manometers, etc.), gas household heating appliances (gas stoves, boilers, direct-flow water heaters, etc.) in gas control units and installations, as well as in other technological gas-air lines, where the operating environment purification from the mechanical particles is required.

An application of gas filters on the pipeline allows a significant service life increase and reliability of the shut-off and control fittings unit, measuring instruments and other devices.

OPERATING PRESSURE:

Gas filters (FH series) are manufactured in versions with maximum operating pressure up to 3 bar (0.3 MPa), up to 6 bar (0.6 MPa) and up to 16 bar (1.6 MPa). Maximum operating pressure is the highest overpressure, when the declared filtration characteristics of the operating environment are provided.

DIAMETER NOMINAL:

From 15 up to 300 mm

HOUSING MATERIAL:

- steel: DN 15÷300;

- iron cast: DN 150, DN 200;

- aluminum: DN 15÷200.

CLIMATIC VERSION:

- -30…+60 °С version – installation in irregularly heated rooms;

- -45…+60 °С version – installation under roof;

- -60…+60 °С version – installation under roof;

- -60…+60 °С version – outdoor installation.

HOUSING VERSION:

Linear (standard) version

Angle version

Standard (linear) version of gas filters is applied onto the straight sections of the pipeline. Angle version of the filter is used at facilities with limited space (gas-distributing plant, distribution pressure reducing station, etc.). Application of the angle version can reduce the number of welds and joints when arranging the corner sections of the pipeline.

Flange connection (DN15÷300)

Coupling connection (DN15÷50)

Gas filters with flange connection are manufactured with PN 6 (standard) or PN 16 (upon request) flanges.

FILTRATION DEGREE:

TERMOBREST filters are manufactured in standard version with a filtration degree of 50 microns.

We can also produce filters with different filtration degrees: 2 microns, 5 microns, 10 microns, 20 microns, 400 microns, 600 microns, 800 microns.

THERE ARE TWO TYPES OF FILTERING ELEMENTS (CARTRIDGES), WHICH ARE USED IN THE FH SERIES MODELS:

- Filtering pad - is a fibro porous polymer material that provides fine filtration (from 2 up to 50 microns) and it has an improved operational factor in terms of strength, permeability and rigidity compared with other types of fine purification filtering elements. Servicing (cleaning) of such filtering element can be carried out by blowing with compressed air or rinsing in water using detergents;

- Strainer - is a stainless steel grid with a mesh of various sizes, for example, 400 microns, 600 microns, 800 microns. It has low resistance factor, long service life, the replacement is not required and it can be cleaned several times.

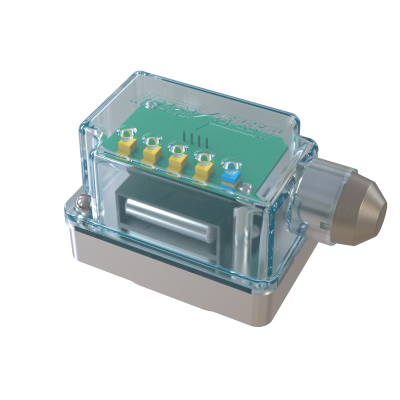

CONTROL OF FILTERING PADS (ELEMENTS) CONTAMINATION DEGREE:

To control the contamination degree (pressure drop) of filtering element different types of contamination indicators can be installed on the filter:

Fig. 1

Fig. 2

Fig. 3

Fig. 4

- Mechanical type of contamination indicator – control of the degree of contamination of the filtering element is carried out visually, using to the inspection window overlap by the indicator element;

- Electric type of contamination indicator with power source mains-operated 24V AC/DC – filtering element contamination control is carried out visually on the LED scale, as well as using a feedback signal (4…20 mA) to the automatic equipment;

- Battery-operated electric type of contamination indicator – filtering element contamination control is carried out visually on the LED scale, by pressing the button on the pressure drop indicator housing;

-

Arrow type contamination indicator – control of the degree of contamination of the filtering element is carried out on a scale (dial plate) with indicating arrows. The scale is divided into segments that indicate the actual pressure drop on the filter from 0 to 30 kPa. There are the indicating drop values through 5 kPa (0, 5, 10, 15, 20, 25, 30 kPa) on the scale for the convenience of contamination control.

The black arrow indicates the actual pressure drop on the filter at the exact moment of operation. It is required to set manually the permissible pressure drop on the filter using red arrow on the scale. When the black and red arrows reach or coincide, the filtering element should be cleaned or replaced.

Depending on the position of the indicator’s visual scale concerning the direction of gas flow through the filter or pipeline, the arrow type contamination indicators are available in two versions: "left-to-right" and "right-to-left".

ADDITIONAL FUNCTIONS AND DEVICES:

All models of gas filters (DN 25÷300 mm) can be equipped with a condensate outlet for draining condensate without demounting the filter or dismantling it from the pipeline.

-------------------------------------

If you need help to select necessary equipment, you should visit our web-site or contact our specialists by e-mail info@termobrest.ru or by phone:

+375 (162) 53-64-13 (technical consultation line);

+375 (162) 53-64-76 (sales and logistics department).

SOLENOID SAFETY GAS VALVES BLOCK UNIT

Solenoid safety gas valves block unit is a set of solenoid safety gas valves and other gas fittings unit assembled into a single gas train (gas filter, pressure regulator-stabilizer, safety relief gas valve, safety shut-off gas valve, pressure switch, etc.) and motorized gas valve

Motorized gas valve included in the unit controls the gas supply to the gas burner and regulates the gas flow rate.

Upon customer's request, the valve block can be manufactured complete with additional automation devices (pressure switches, position indicators of valves), as well as in general industrial and waterproof versions.

The gas block can be designed according to the scheme, which provides the possibility to check the tightness of the valves included in the block before ignition of the burner.

FLOW CONTROL RANGE:

- 0.05 to 100 % of nominal.

TYPE OF REGULATION:

- proportional;

- position control;

- manual regulation.

DIAMETER NOMINAL:

- DN 15÷300.

HOUSING MATERIAL:

- steel: DN 15÷300;

- iron cast: DN-150, DN-200;

- aluminum: DN 15÷200.

CLIMATIC VERSION:

- -30…+60 °С – installation in irregularly heated rooms;

- -45…+60 °С – installation under roof;

- -60…+60 °С – installation under roof;

- -60…+60 °С – outdoor installation.

AMBIENT OPERATING TEMPERATURE:

All solenoid safety gas valves block units manufactured by TERMOBREST are supplied in a version with ambient operating temperature from -60 up to +70 ° C.

Upon customer’s individual request, solenoid safety gas valves block units can be manufactured with ambient operating temperature from -45 up to +120 ° C.

Upon customer’s individual request, the valves block units with the read-off position indicators can be manufactured with ambient operating temperature from -45 up to +90 ° C (the upper range is limited by the permissible operating limit (range) of the read-off position indicator).

-------------------------------------

If you need help to select necessary equipment, you should visit our web-site or contact our specialists by e-mail info@termobrest.ru or by phone:

+375 (162) 53-64-13 (technical consultation line);

+375 (162) 53-64-76 (sales and logistics department).